Etching parameter optimization is another important part after the etching method and etchant are determined. Alfa Chemistry has been deeply engaged in etching parameter optimization for many years and has rich experience. Our team is confident that we can help you reduce the risk of failed process validation, shorten the research cycle and reduce the research cost by optimizing the etching parameters.

Our Optimization Scope

Alfa Chemistry has ability to optimize the etching parameters, including but not limited to the following.

- Etching rate

Etching rate is the speed of etching process for a material. Etching rate is determined by measuring the depth achieved by etching in a period of time. It is reported as distance/time with typical units are angstroms/second, nanometers/minute and microns/minute. In general, deep etching depths would benefit from fast etching rate to enhance productivity while shallow etching depths would benefit from slow etching rate to provide accurate depth control. The etching rate of wet etching depends on the etching solution composition, concentration and temperature. The etching rate of dry etching is affected by gas composition, gas flow rate, substrate temperature, ion energy and incidence angle. - Etching selectivity

Etching selectivity is the ratio of etching rate between different materials. The formula for etching selectivity is:

Selectivity = Etching rate A/Etching rate B

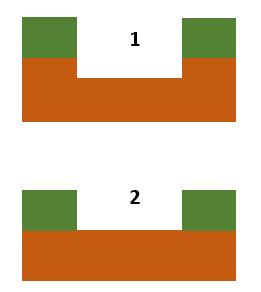

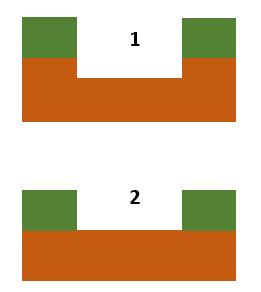

It is often used when describing the relative etching rate between the etching target film and underlying film or mask. The parameter indicates how much underlying film or mask is etched as target film is etched. Lower etching selectivity means that the etchant will not only remove the top film but also attack the underlying film or mask. Higher etching selectivity means that less underlying film or mask is etched away. Understanding etch selectivity is important to successfully determine mask thickness and control the etching results.

Figure 1. Etching effect of lower (1) and higher (2) etching selectivity.

Figure 1. Etching effect of lower (1) and higher (2) etching selectivity.

Alfa Chemistry has a professional semiconductor technology team. We are well versed in optimization of etching rate, etching selectivity and other etching parameters. No matter you have any questions about etching parameters, please do not hesitate to contact us and we will answer you as soon as possible.

Our Order Process

- Handling your enquiry: All working relationships begin with an initial message or call, to let us know about your difficulties with etching parameter optimization.

- Processing your order: Once we have agreed costings and timescales, our team will propose etching parameter optimization solutions and finish the optimization as soon as possible after your confirmation.

- Shipping your order: A complete etching parameter optimization report will be finished and ship to you in the shortest possible time.

- Payment and aftercare: We have a dedicated sales team who will be in touch regarding invoicing and payment. Should you have queries, we can help.

Why Choose Us?Alfa Chemistry is the premier choice for all semiconductor manufacturing and research institutions. We are dedicated to optimizing etching parameters for improving product yield. With high service efficiency, guaranteed design scheme and competitive price, Alfa Chemistry will offer a pleasant cooperation to you. Our customer service team is available to help you with any questions, please do not hesitate to contact us. We look forward to maintaining a harmonious, long-term and win-win cooperative relationship with you.

Figure 1. Etching effect of lower (1) and higher (2) etching selectivity.

Figure 1. Etching effect of lower (1) and higher (2) etching selectivity.